CeraCAT® Ceramic Catalytic Filter

for dust removal,denitration,desulfurization and dioxin elimination

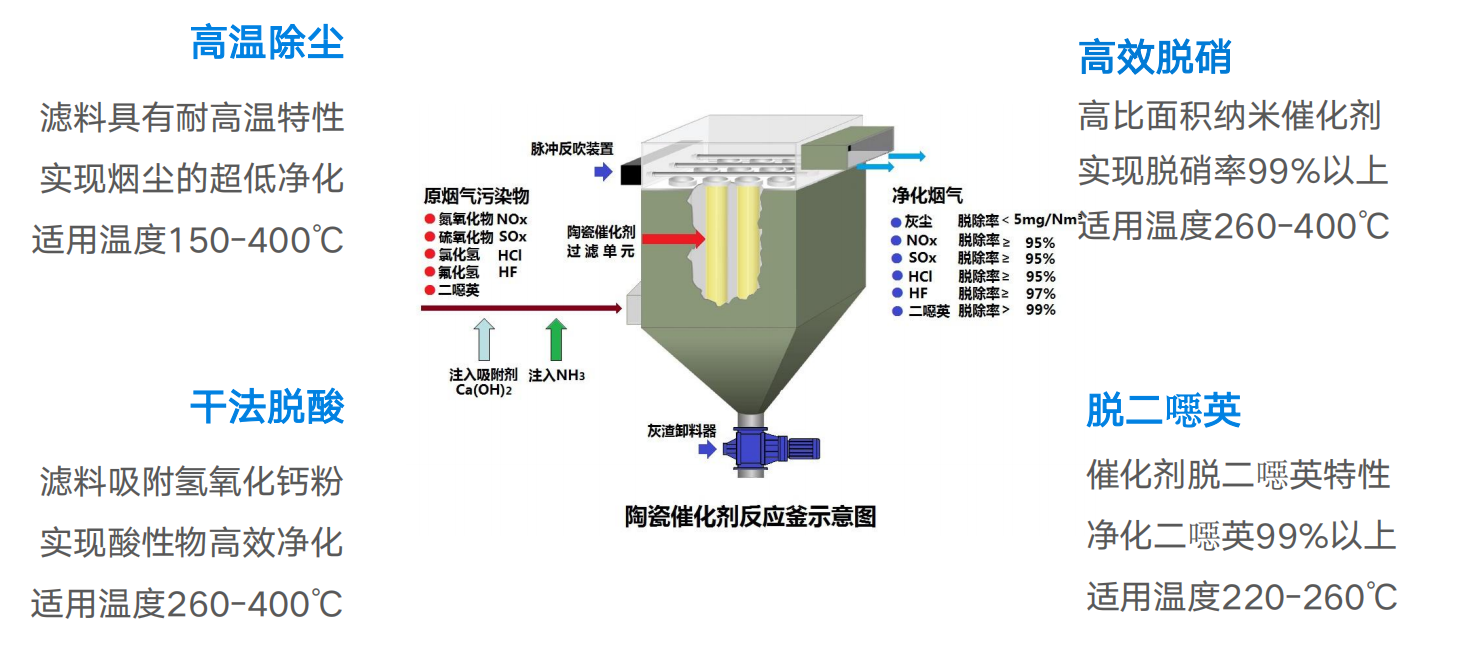

Application:Industrial kiln exhaust gas denitrification(DeNOx), dust removal(DeDust), desulfurization(DeSOx), dioxin removal, acidic component removal, etc.

Performance:

- Dust removal efficiency ≥ 99% (typical particle emission concentration<5mg/Nm3, minimum<1mg/Nm3).

- Denitrification efficiency ≥ 95% (typical NOx emission concentration<100mg/Nm3, minimum<2mg/Nm3).

- Desulfurization efficiency is ≥ 95% (typical SO2 emission concentration<50mg/Nm3, minimum<2mg/Nm3).

- Dioxins elimination efficiency is ≥ 99%.

- Other acidic components removal efficiency is ≥ 95%.

Temperature:

- Medium temperature series: 280-400 ° C

- Low temperature series: 200-280 ° C

Patent: Ceramic fiber cotton shearing technology, nano vanadium titanium catalyst impregnation technology.

Features: high porosity (>80%), high strength, low resistance (<300pa per meter per minute), and ultra long lifespan. Completely replace the process of bag bag+desulfurization tower+SCR/SNCR

Service life: 5-year warranty, with a service life of 8-10 years under specific conditions.

Typical process: Ceramic integrated process.

Application scenarios: glass kilns, coking industry, waste fuel, steel industry, industrial boilers, sintering boilers, etc.

ZTW CeraCAT ceramic catalytic filter is a new integrated ceramic desulfurization, denitrification, and dust removal process technology that replaces traditional SCR/SNCR technology. It adopts self-developed nano vanadium titanium catalyst impregnation technology, which combines the ceramic fiber filter and the nano vanadium titanium catalyst.

Firstly, it inherits the advantages of ultra-high porosity, air to cloth ratio, and ultra small nanoscale pore size of ceramic fiber filter tubes, and can achieve 99% of industrial dust and particulate matter including PM10, PM2.5, PM1, etc;

Secondly, by utilizing the gradient pore structure inside the filter tube and the synergistic effect of catalysts, combined with denitrification agents such as ammonia and urea, efficient NOx removal of over 95% -99% can be achieved at high temperatures of 280-400 ℃ (typical NOx emissions<100mg/Nm3, and even<2mg/Nm3 according to emission requirements);

Thirdly, a unique adsorbent filter cake is formed on the surface of the ceramic filter tube, and desulfurization agents such as lime powder are used in conjunction with the ceramic catalytic filter tube to efficiently remove over 95% -99% of SO2 and other acidic components (typical SO2 emissions<50mg/Nm3, and even<2mg/Nm3 according to emission requirements);

Fourthly, the nano vanadium titanium catalyst has the characteristic of removing dioxins, and can achieve over 99% removal of dioxins.

Compared with the traditional process of bag bag+desulfurization tower+SCR/SNCR, the ceramic integrated process using ceramic catalytic filter tubes can simultaneously use desulfurization, denitrification, and dust removal to remove pollutants such as dioxins in a single section, saving more than 50% of the area. Moreover, it can solve the problem of catalyst poisoning caused by high alkali metal dust. Ceramic filter tubes have corrosion resistance and wear resistance characteristics, with a service life of over 5 years, and can even reach 8-10 years under specific working conditions.

Ceramic catalytic filter is based on ceramic fiber filter impregnated with nano vanadium titanium catalyst.

For the production process, raw material characteristics, and process flow of the filter tube, please refer to the Powfrax® ceramic fiber filter

Deep impregnation technology of nanoscale catalyst slurry with independent patents

Ordinary Method

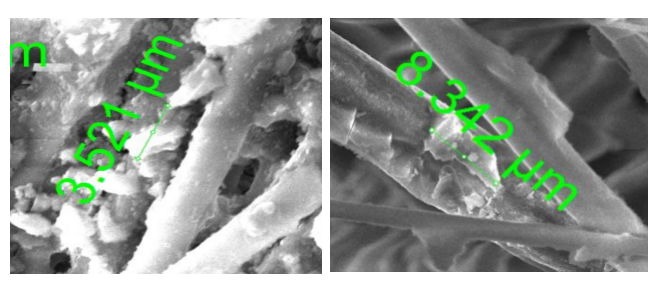

- 1. Traditional process catalyst impregnation can only achieve micrometer level catalyst adhesion。

- 2. Competitor catalysts have low permeability when impregnated with slurry, but only adhere to the surface and shallow layers.

- 3. The uneven distribution of the impregnation slurry of competing catalysts affects the denitrification efficiency.

Patent technology

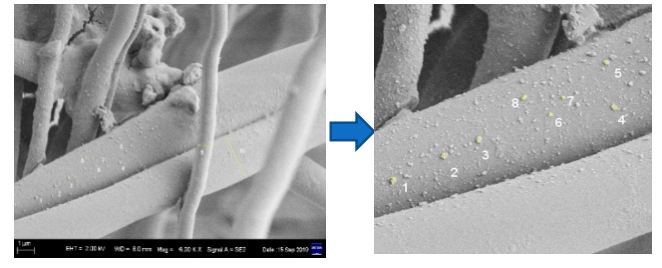

- 1. Nano scale catalyst slurry with an average catalyst loading of less than 0.1um

- 2. Immerse deeply for more than 6 hours and fully immerse over 100 layers of filter paper.

- 3. Dynamic impregnation ensures even distribution of catalyst load.

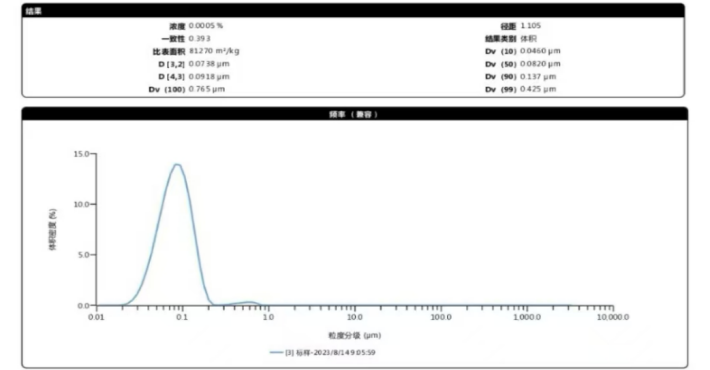

Characteristics of catalyst slurry

The catalyst slurry is loaded with vanadium titanium nanomaterials to form a uniform suspension. The particle size D50 of the active component is around 100nm, and its particle specific surface area is as high as 80 ㎡/g.

Particle size analysis of vanadium titanium nanocatalyst loaded with laser

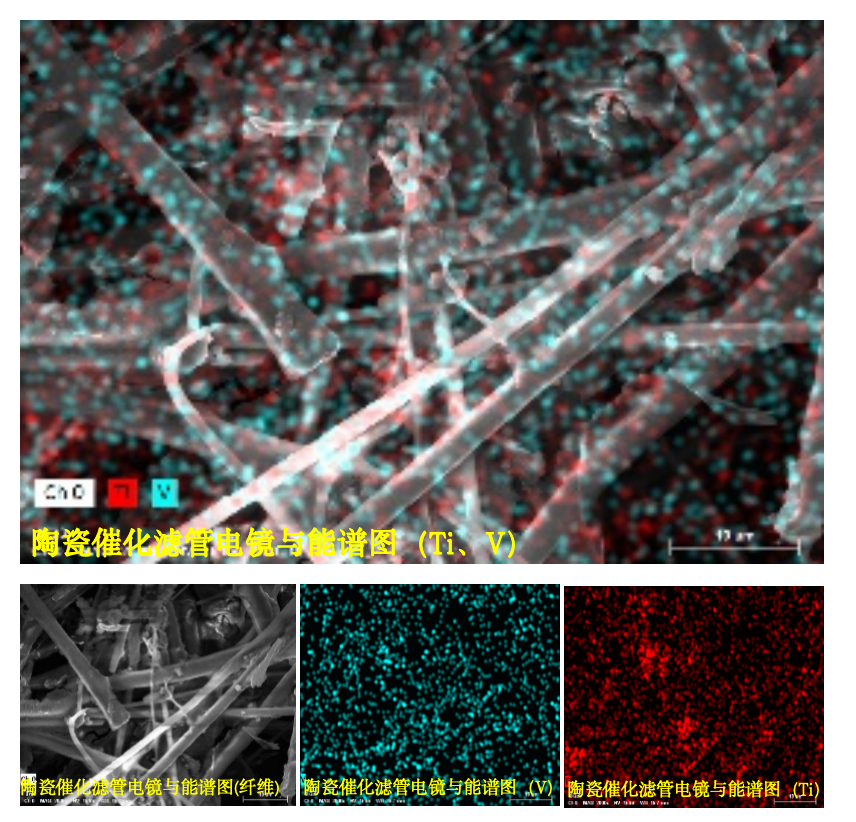

Electron microscopy and energy spectrum of ceramic catalytic filter

Ceramic Integrated Gas Treatment Technology

In 2018, The Ceramic Catalyst Multi pollutant Collaborative Control Technology was selected for the "2018 National Advanced Pollution Prevention and Control Technology Catalogue (in the field of air pollution prevention and control)" by the Ministry of Environmental Protection.

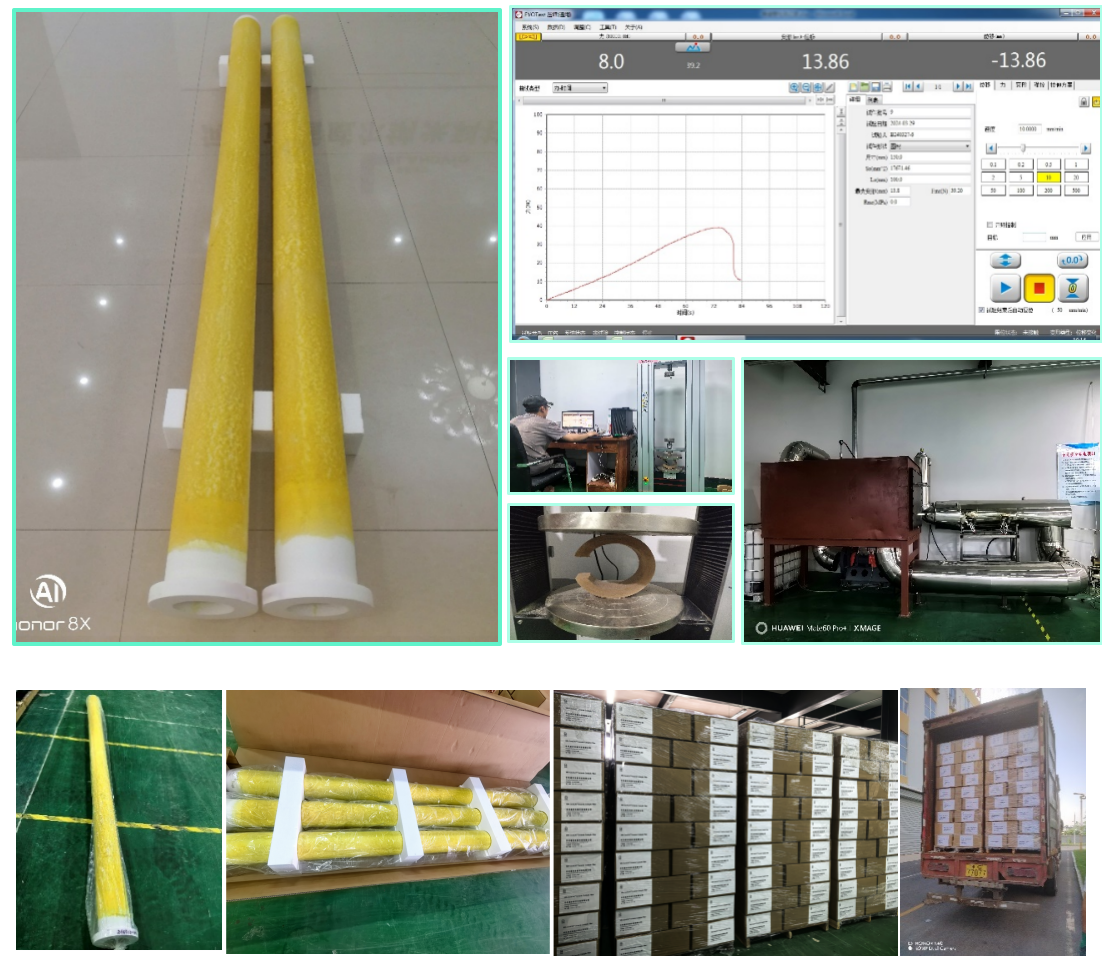

Ceramic catalytic filter production process

Production of Ceramic Fiber Filters

Ceramic fiber filters are produced according to high-quality standards. The production process is as follows:

powfrax-dedust-ceramic-fiber-filter-element

Nano-catalyst deep impregnation

The dynamic deep immersion of nanoscale catalyst slurry exceeds 6 hours, with an average catalyst loading of<0.1um, uniform distribution of catalyst loading, and over 100 layers of filter paper fully immersed

Drying stage

After 15 to 20 hours of continuous low-temperature drying, the drying quality is ensured without damaging the internal structure.

Quality Control and Packaging and Shipping

At each stage mentioned above, the quality inspection department will check the quality parameters of the finished products at each stage to ensure high-quality production. After production is completed, the strength, pressure difference, porosity, density, appearance, size, etc. of each batch of ceramic filter elements will be inspected, and an inspection report will be issued. The strict quality inspection throughout the entire process not only ensures product quality, but also forms the only unalterable and traceable quality report.

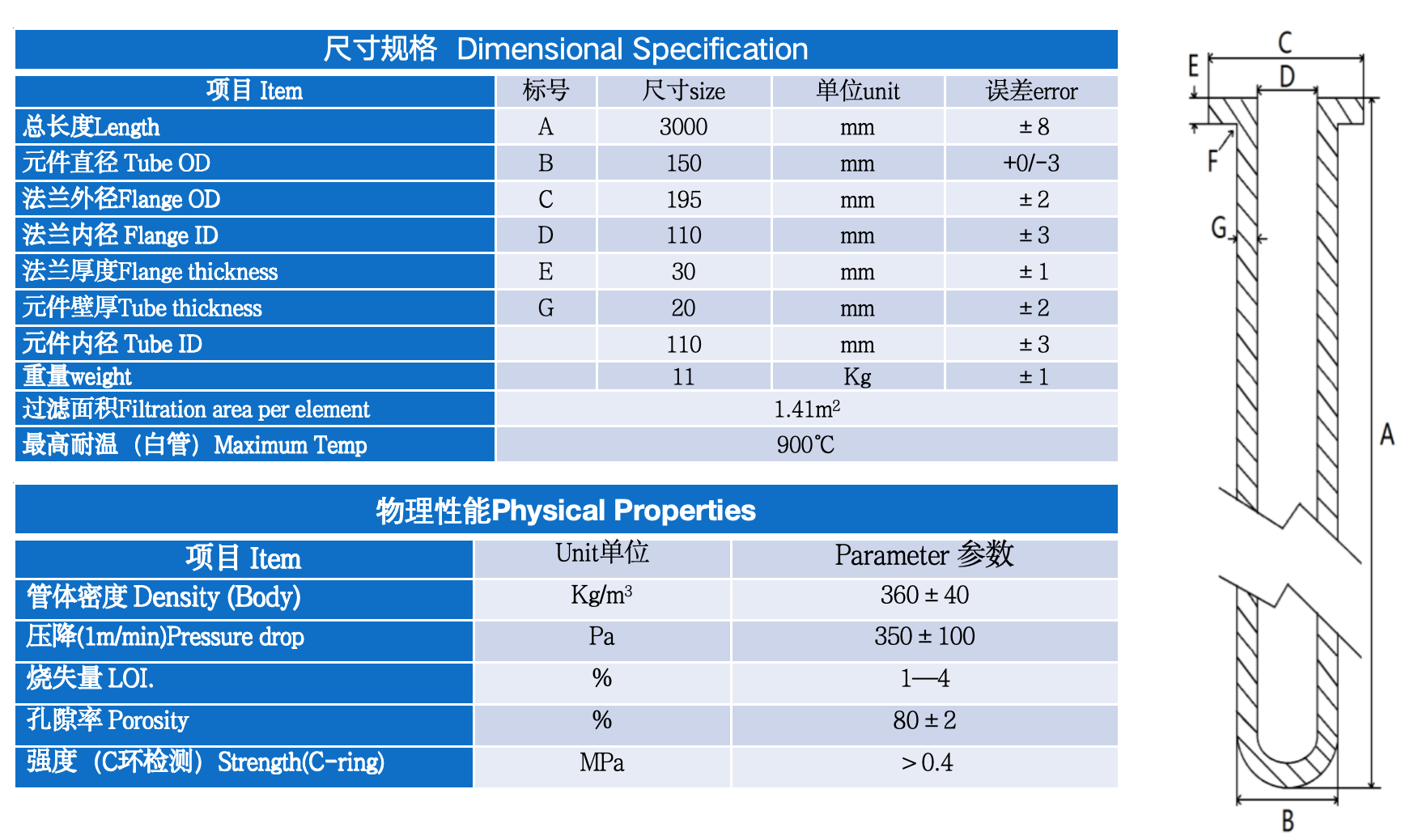

Ceramic Fiber Filter Parameter

Our customers

Since 2017, we have implemented over 50 glass furnace ceramic integrated flue gas purification projects for companies such as Wuliangye in Yibin, Shandong Pharmaceutical Glass, Sichuan University of Science and Technology, Anhui Shengshi, Shandong Luzhong, Shandong Jingyao Glass, and Luzhou Huasheng. Among these, the "Luzhou Liquor Industry" three-line air glass melting furnace environmental protection project is the first third-party operation project in China for daily glass furnace air pollution control adopting an "investment + operation" model. The "Sichuan University of Science and Technology" full-oxygen glass melting furnace is the first environmental protection project in China to use ceramic filter tubes + SCR denitrification technology for full-oxygen glass melting furnaces.

Ceramic Catalytic Filter FAQ

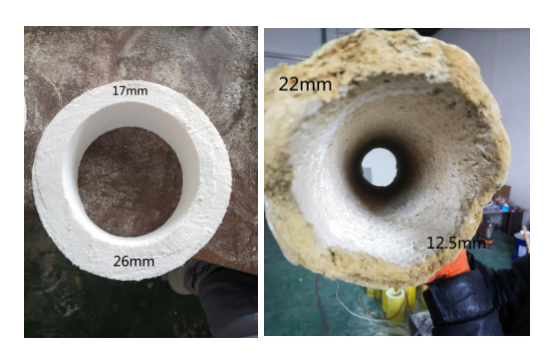

1. Flange crushing or breaking

The flange cracking or breaking is due to insufficient curing strength. Usually, conventional curing is used, with a flange thickness of 30mm. If the flange generally has a curing depth of less than 10mm, or even only 6-8mm, and 10-15mm in the middle sandwich is not cured, resulting in insufficient hardness of the flange and easy to damage during operation. ZTW Powfrax ceramic fiber filter tube is deeply cured, with the middle sandwich <10mm, usually 5-8mm, so the flange strength is high.

2. Ceramic fiber filter body hole or broken

There are two main reasons for the holes in the ceramic fiber filter tube during operation: First, the poor layering of the centrifugal fabric of the ceramic fiber filter tube molding and the small discharge volume, resulting in the small volume density of the ceramic fiber filter tube body and the low backblowing wear resistance strength; Second, there are defects in the flange side of the ceramic fiber filter tube with a small volume density defect and the unreasonable design of the backblowing system, which makes its backblowing pressure too large, and it will also cause severe wear and damage to the inner wall at the front 500mm of the flange side due to long-term backblowing wear.

Flange crushing or breaking - Low flange strength

Holes in ceramic filter - Reverse blowing pressure or uneven wall thickness, poor inner wall strength

Breakage occurs 30-60cm from flange - Process defect causing low strength of ceramic filter tube 30-60cm in length

Large deviation in inner wall thickness - Process defect causing

The green filter tube indicates that the vanadium catalyst on its surface is a mixture of V⁵⁺ and V⁴⁺, both of which exist at the same time and have a comparable proportion, making the overall appearance appear green. Although V⁴⁺ also has certain catalytic activity, it is generally believed that V⁵⁺ is the most active valence state in SCR reactions. Therefore, a green filter tube may mean that its initial activity is slightly different from that of a yellow filter tube. Only during use, the oxygen in the flue gas is gradually reoxidizing V⁴⁺ to V⁵⁺.

In addition, in the drying process, the temperature and ventilation smoothness of the ceramic catalytic filter tube are key factors affecting the color of the filter tube. The temperature must be strictly controlled and the air in the drying box must be smooth.

\n1.From the perspective of the denitrification mechanism of SCR plate catalysts, the vanadium titanium (V-Ti) component of the SCR plate catalyst comes into direct contact with smoke, pollutants SO2, HF, NOx components, and ammonia from the decomposition of reducing agent urea and urea impurities. Therefore, the SCR plate catalyst is highly prone to deactivation or poisoning.

\n2.From the perspective of the detachment mechanism of ceramic catalytic tubes, the first step is to efficiently purify smoke, acidic components, and urea impurities. At the same time, before using ceramic filter tubes, it is necessary to pre coat the surface of the ceramic filter tube with calcium hydroxide powder as a protective layer. The protective layer has good adsorption and will not fall off during operation, which will effectively protect the surface layer of the ceramic filter tube and will not cause wear or tear on the surface of the filter tube. In other words, urea impurities will not have direct contact with the surface of the ceramic catalytic tube. Even if there is contact, it may only reduce the activity of the 0.5mm catalyst on the surface layer of the ceramic filter tube or cause poisoning of the surface catalyst, but it will not cause deactivation or poisoning of the deep catalyst in the ceramic tube.

\n1.If the flue gas temperature is lower than 220 ℃ and the sulfide SOx is higher than 50mg/Nm ³ during long-term operation, the catalyst in the ceramic catalytic tube will reduce its activity or desorption efficiency to below 70%.

\n2.Its characteristic is a decrease in denitrification efficiency. Even with the addition of reducing agent urea, its denitrification efficiency cannot be increased. The solution is to activate and regenerate the independent reaction vessel chamber at high temperature, with a temperature higher than 350 ℃ and a continuous high temperature of more than 24 hours.

Method for reducing filter activity: When the flue gas temperature is above 290 ℃, a handheld flue gas analyzer is used to detect the NOx concentration at the outlet of the purification chamber of the reaction kettle. At the same time, the original NOx concentration of the flue gas in front of the reaction kettle should also be detected. By comparing the NOx concentration in the purification chamber with the original concentration, the stripping efficiency is calculated to determine whether the ceramic tube catalyst is deactivated.

\n2.Factors affecting lifespan——

(1). Reasonable blowback pressure to avoid significant wear on the 300mm inner wall area of the ceramic pipe flange caused by high-pressure blowback.

(2). Ceramic tube fiber sheet sealing gaskets need to be replaced once every 1-2 years. For gaskets with corrosion or poor sealing, they need to be replaced in a timely manner, otherwise it may cause damage to the filter tube or reduce its service life.

(3). The purification indicators of fluoride and boride in the main flue gas must be below 20mg/Nm ³.

(4). Avoid long-term operation at temperatures below 220 ℃ and avoid frequent high temperature regeneration and activation of the catalyst.

\n1.Analyzing the distribution of vanadium and titanium components in ceramic tube nanocatalysts through electron microscopy and energy spectrum analysis, is there a serious problem of sintering or nanoparticle aggregation?

\n2.Analyzing the serious migration problem of vanadium V nanoparticles in ceramic tube catalysts? Is there a significant deviation in the atomic V/Ti percentage ratio for analysis (refer to the standard range of 0.16-0.28)? Determine whether there is a significant migration of V component (such as less than 0.06).